Incoloy 825 (UNS N08825) is a titanium-stabilized, austenitic nickel-iron-chromium alloy with additions of molybdenum and copper. It was developed to withstand aggressive mixed acid conditions, particularly those involving oxidizing and reducing species at elevated temperatures. Its exceptional resistance to stress corrosion cracking (SCC), acid attack, and intergranular corrosion has led to its extensive adoption in nuclear fuel reprocessing, acid regeneration units, and sour oil & gas environments.

This article explores the metallurgical behavior, corrosion resistance, and SCC performance of Incoloy 825, with a particular focus on its role in environments containing chlorides, nitrates, and sulfuric acid—a common cocktail in nuclear and heavy chemical plants.

The nominal composition of Incoloy 825 is as follows:

| Element | Content (wt%) |

|---|---|

| Nickel (Ni) | 38–46 |

| Chromium (Cr) | 19.5–23.5 |

| Iron (Fe) | Balance |

| Molybdenum (Mo) | 2.5–3.5 |

| Copper (Cu) | 1.5–3.0 |

| Titanium (Ti) | 0.6–1.2 |

| Carbon (C) | < 0.05 |

| Other (Mn, Al, Si, N) | Trace |

Key design advantages include:

Ni-Cr balance to protect against oxidizing acids (e.g., HNO₃, H₂SO₄).

Mo and Cu for resistance to reducing acids (e.g., HCl, phosphoric acid).

Ti stabilization to prevent sensitization during welding or long-term thermal exposure.

The result is a fully austenitic FCC microstructure, with high phase stability and low susceptibility to carbide precipitation at grain boundaries.

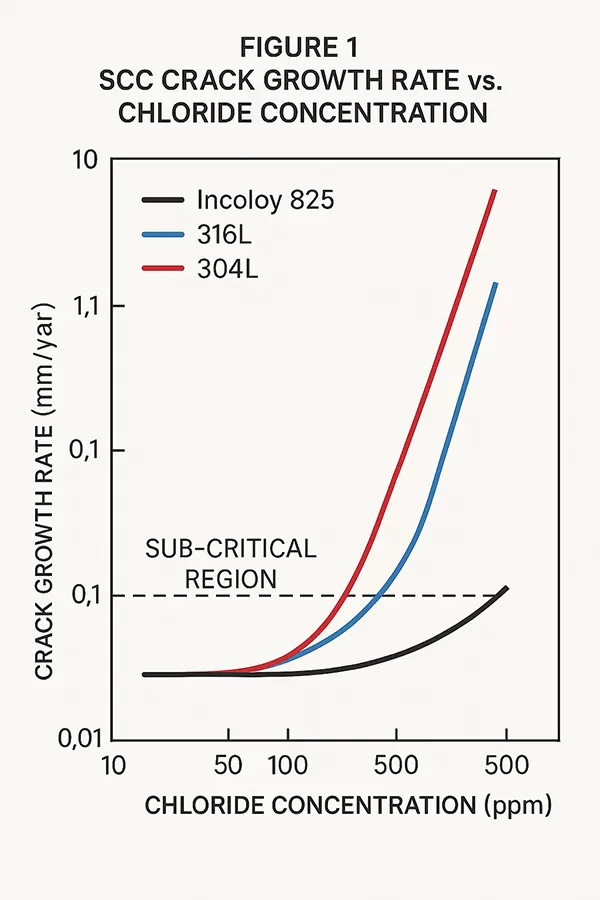

SCC is a form of environmentally assisted cracking caused by the simultaneous presence of tensile stress, a corrosive medium, and a susceptible microstructure. In chloride-containing acidic environments, many stainless steels fail catastrophically due to SCC.

Incoloy 825’s high nickel content (>40%) and stabilized structure provide excellent immunity.

In nuclear reprocessing, industrial waste systems, and H₂SO₄ regeneration units, the following are commonly found:

H₂SO₄ + Fe/Cr oxides

HNO₃ + Cl⁻ traces

Hydrofluoric acid vapors

Incoloy 825 exhibits:

Stable passive film formation in oxidizing media.

Resistance to localized corrosion in reducing acid systems.

No pitting or crevice corrosion up to 100°C in 20% H₂SO₄ with 500 ppm Cl⁻.

No transgranular SCC up to 70°C in 10% HNO₃ + 100 ppm Cl⁻.

These properties ensure that it outperforms many duplex and even superaustenitic steels in complex acid handling units.

High-temperature operation in radiation or heated acid environments requires:

Resistance to thermal sensitization and carbide precipitation.

Stability of passive film at elevated temperatures.

Incoloy 825 remains stable up to 540–600°C. Long-term aging studies (10,000 hr at 550°C) show:

No intergranular attack or grain boundary carbide precipitation.

Retention of >85% yield strength.

Minimal change in SCC threshold stress intensity.

Microscopic images (not shown) reveal fully equiaxed grain structure and absence of γ′ or intermetallic phases post-aging.

Incoloy 825 is:

Readily cold-formed and roll-bent without cracking.

Weldable using GTAW, SMAW, and GMAW methods.

Not prone to HAZ sensitization, unlike 316L or 904L.

Filler metals such as ERNiFeCr-1 or ERNiCrMo-3 provide excellent joint strength and corrosion resistance. Post-weld testing confirms:

No SCC crack initiation at weld toe.

Creep-rupture strength >100 MPa at 600°C over 1000 hours.

Nuclear Reprocessing Plants: Incoloy 825 is used in high-level liquid waste evaporators, acid feed lines, and recovery systems due to its resistance to HNO₃ + Cl⁻ mixtures and radiation exposure.

Sulfuric Acid Plants: In absorber towers and acid coolers, it resists high Cl⁻-laden acid droplets at 80–120°C.

Oil & Gas Industry: Used in sour gas tubing, acid gas scrubbing, and downhole tools where high H₂S + CO₂ + Cl⁻ coexist.

| Property | Incoloy 825 | 316L SS | Alloy 20 | C-22 |

|---|---|---|---|---|

| Ni Content (%) | ~42 | ~10 | ~32 | ~57 |

| SCC Resistance in Cl⁻ | Excellent | Poor | Good | Excellent |

| Weldability | Excellent | Excellent | Moderate | Moderate |

| Long-term Thermal Stability | High | Low | Moderate | Very High |

| Cost | Moderate | Low | Moderate | High |

Incoloy 825 offers a balanced solution between low-cost austenitics and expensive Ni-based C-alloys.

Avoid fluid stagnation: ensure flow velocities >1 m/s.

Design for maximum allowable Cl⁻ levels: recommend <500 ppm in acid mix for continuous service.

Include radiation shielding if exposed to high neutron flux.

Use expansion joints or bellows made of Incoloy 825 in high-cycle components.

With growing emphasis on:

Nuclear waste management

Sulfur recovery from flue gas

Hydrometallurgy and rare-earth extraction

Incoloy 825 is expected to play a larger role. Ongoing developments include:

Hybrid cladding systems: Incoloy 825 cladding over carbon steel vessels.

Advanced welding consumables for heavy-wall nuclear piping.

Integration with supercritical acid recovery loops.

Its success is not only due to its chemistry, but also to its fabricability, weldability, and in-service durability, making it one of the most practical high-nickel alloys in use today.

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China