Specifications: AMS 5662, NACE MR-01-75, AMS 5663, ASME SB637, ASTM B637

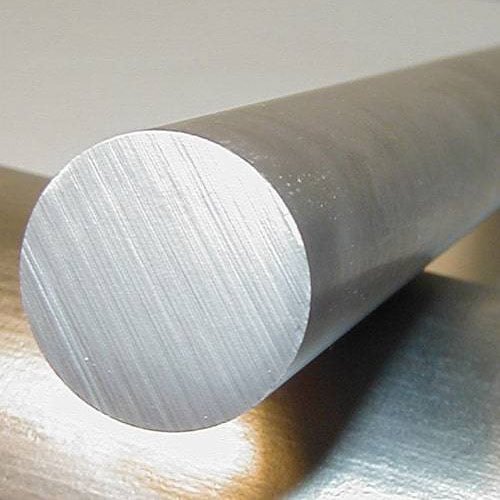

Sizes: Dia: 3 - 600 mm, Length: 0.5 - 6.0 meter

Condition: Cold-worked, Hot worked, PH, H&T, Annealed

Form: Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Billet, Ingot, Forging.

Tolerances: K10, H11, H8, H12, K11, H9, H10, K9, K12, H13

Inconel 718 Round Bars provide the following universal performance characteristics:

Good weldability & formability

High durability in environments with temperatures of up to 1300° F

Excellent oxidation resistance

Superior cryogenics properties

Specifically, alloy 718 effectively resists stress rupture and creep when exposed to temperatures as hot as 1300°F, and maintains corrosion resistance below the 1800° threshold. Moreover, its tensile strength and impact resistance remain intact at temperatures in the cryogenic range, making it particularly useful for aerospace applications.

Alloy 718 is classified as "age-hardenable," meaning that its resistance properties increase over time—especially with prolonged exposure to cold temperatures. Numerous AMS and NACE specification processes can be deployed to customize its application-specific performance characteristics. Additionally, heat treatments can be used to soften the alloy prior to welding, forming or machining. Its machinability rating is 12% of B-1112, and it has typical stock removal rates of 20 surface feet per minute with high-velocity tools and 80 surface feet per minute with carbide tools.

|

SPECIFIC GRAVITY |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

7.98 g/cm3 |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

TYPICAL APPLICATIONS |

RELATED SPECIFICATIONS |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Land based gas turbine engines Jet Engines Fasteners Instrumentation parts Mandrels Well head completion equipment |

AMS 5662 AMS 5663 UNS N07718 ASTM B637 W.Nr 2.4668 MSRR 7114 MSRR 7115 NACE MR0175 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

CHEMICAL COMPOSITION |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

MECHANICAL PROPERTIES IN SOLUTION ANNEALED AND AGED CONDITION FOR AEROSPACE BAR |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

MECHANICAL PROPERTIES IN SOLUTION ANNEALED AND AGED CONDITION FOR OIL PATCH BAR |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China