Specifications: AMS 5666, ASTM B446, ASME SB-446

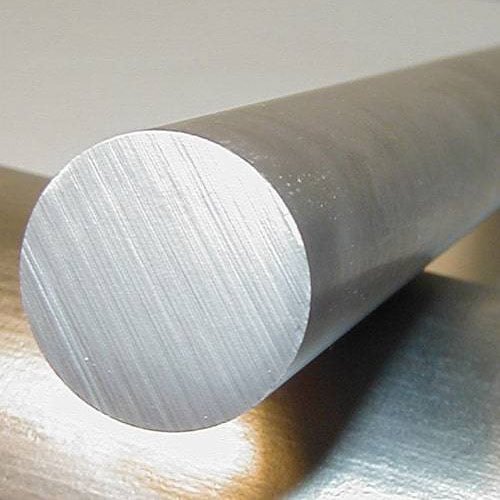

Grade: 625 (N06625)

Size: 5 MM To 500MM

Length: 100MM To 6000 MM Length

Type: Black, Polish, Export

Form: Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Billet, Ingot, Forging.

Inspection, Test Reports: Mill Test Certificates, EN 10204 3.1/3.2, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Non-Destructive Test Reports

Working with this product

Alloy 625 can be cold formed, hot worked, and machined through most standard methods. Hot forming should be done at temperature ranges of 1700 – 2150°F (927-1177°C), and care should be taken when cold working and machining, as it work hardens more quickly than more traditional austenitic stainless steels. Recommend using rigid, powerful machines with sharp tooling at positive rake angles, with tools changed frequently to maintain sharpness. Heavy constant feeds are advised to maintain a positive cutting action with proper lubrication. All 625 may be welded through typical gas shielded processes.

Heat treatment

This alloy has three primary heat treatments – solution annealing at 2000-2200°F (1093 – 1204°C) with air or rapid quenching, annealing at 1600-1900°F (927-1038°C) with air or rapid quenching, and stress relieving at 1100-1600°F(593 – 900°C) with air quenching. Each process results in different characteristics, with the high temperature annealing used for applications above 1500°F where creep resistance is important. The medium temperature annealing provides optimal tensile and rupture properties up to 1900°F (1038°C), while the stress relieved state is recommended for applications under 1200°F (649°C), where maximum fatigue, hardness and yield strength are required.

Chemical Composition

|

Grade |

C |

Mn |

Si |

Cu |

S |

Fe |

Mo |

Ni |

Cr |

|

Inconel 625 |

0.10 max |

0.50 max |

0.50 max |

– |

0.15 min |

5.0 max |

– |

58.0 min |

20.0–23.0 |

Mechanical Properties

|

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

|

8.4 g/cm3 |

1.350 °C (2460 °F) |

Psi – 1,35,000 , MPa – 930 |

Psi – 75,000 , MPa – 517 |

42.5 % |

Equivalent Grades

|

STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

|

Inconel 625 |

2.4856 |

N06625 |

NCF 625 |

NA 21 |

ХН75МБТЮ |

NC22DNB4M |

NiCr22Mo9Nb |

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China