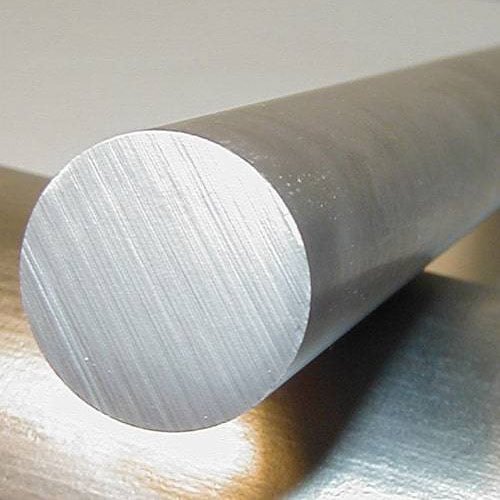

Specification: ASTM B 166 / ASME SB 166 / ASTM B564 / ASME SB564 / AMS 5665

Dimensions: ASTM, ASME and API

Size: 5 mm To 500 mm Dia in 100 mm to 6000 mm Length available with NACE MR 01-75.

Length: 100 mm To 3000 mm Long & Above

Finish: Bright, Polish & Black

Grade: Inconel 600 – UNS N06600

Tolerance: H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements

Grade of Inconel 600 Round Bar

|

STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

|

Inconel 600 |

2.4816 |

N06600 |

NCF 600 |

NA 13 |

МНЖМц 28-2,5-1,5 |

NC15FE11M |

NiCr15Fe |

Chemical Composition of Inconel 600 Round Bar

|

Grade |

C |

Mn |

Si |

Cu |

S |

Fe |

Mo |

Ni |

Cr |

|

Inconel 600 |

0.15 max |

1 max |

0.50 max |

0.50 max |

0.15 min |

6 - 10 |

- |

72 min |

14 - 17 |

Mechanical properties of Inconel 600 Round Bar

|

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

|

8.47 g/cm3 |

1413 °C (2580 °F) |

Psi – 95,000 , MPa – 655 |

Psi – 45,000 , MPa – 310 |

40 % |

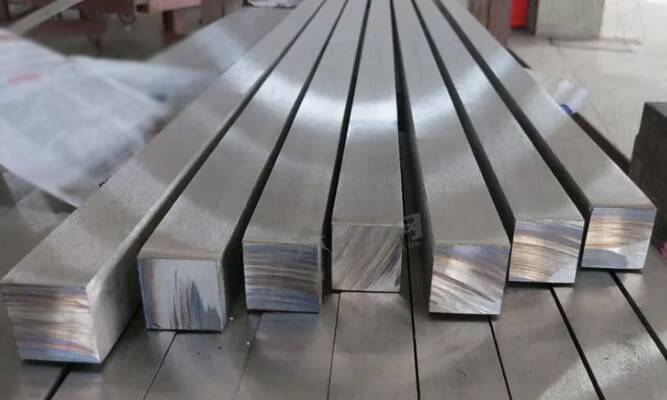

Surface Finish of Alloy 600 Rod

|

CD |

Cold drawn |

P |

Polished |

|

BD |

Bright drawn |

SRE |

Slit rolled edge |

|

CG |

Centreless ground |

HF |

Hot finished |

|

CF |

Cold finished |

HRAP |

Hot rolled annealed and pickled |

|

P&T |

Peeled and turned |

RT |

Rough turned/peeled |

|

ST |

Smooth turned |

PR |

Peeled and reeled |

Inconel 600 Bar Condition

|

H&T |

Hardened and tempered. |

|

ANN |

Annealed |

|

PH |

Precipitation hardened. |

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China