Size Range: 15NB to 150NB

In manufacturing process: Cold drawn/ Extruded

Length: 100 mm To 6000 mm Long & Above

Tolerance : H8, H9, H10, H11, H12, H13, K9, K10, K11, K12 or as per clients’ requirements

Finish : Cold Drawn, Shot Blast & Drawn, 240 Grit Belt Polished, Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish, High Polished

Condition : Cold Drawnd Polished Cold Drawn Centreless Ground & Polished, Threading

Surface : Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline

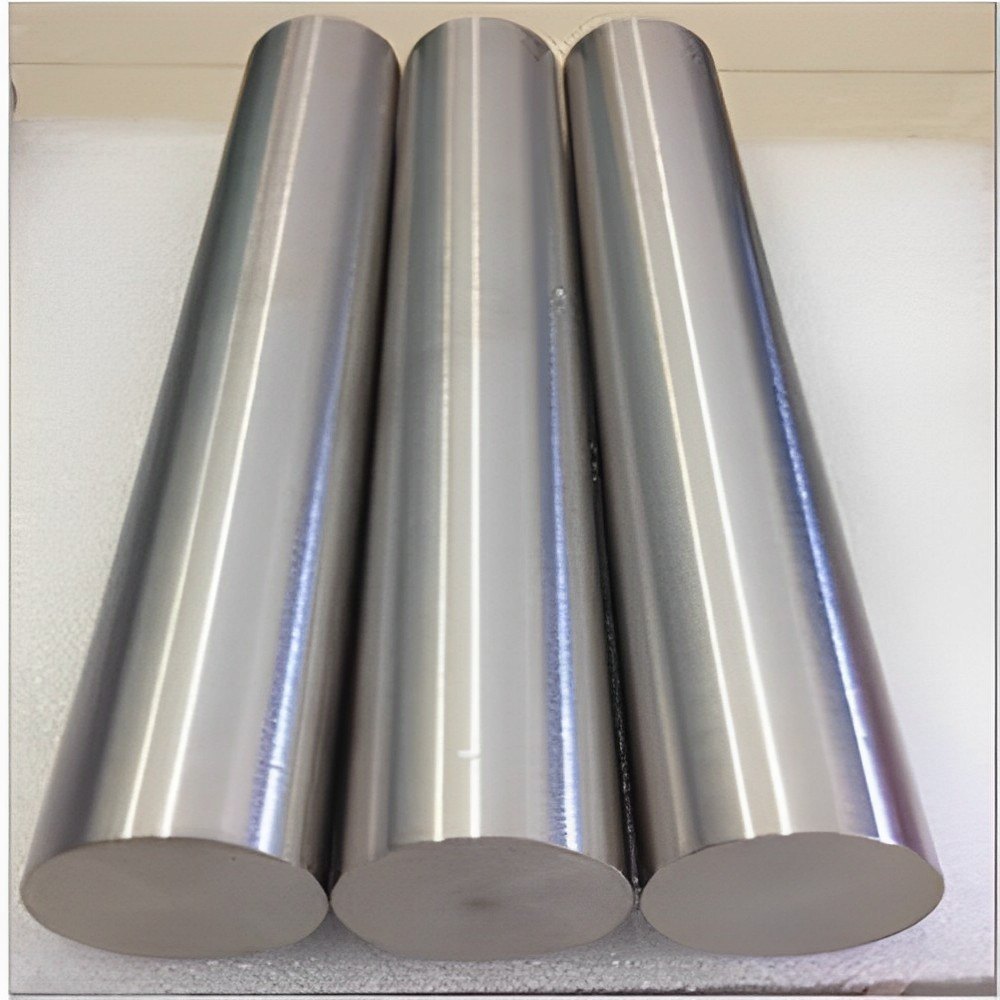

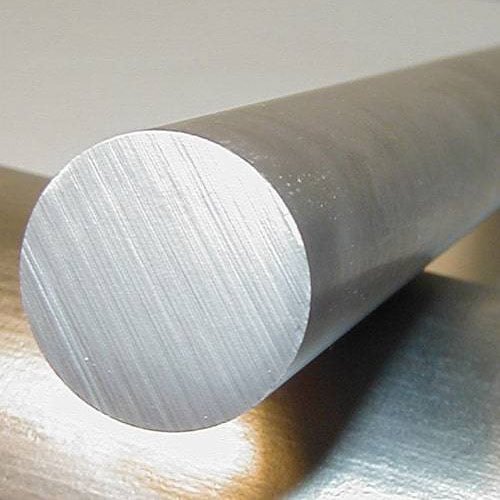

Hastelloy C22 Round Bar Sizes

|

Type |

SIZES (mm) |

SIZES (Inches) |

ISO Tolerance |

|

Cold Drawn and Polish |

3.00 - 75.00 |

1/8 - 3.00 |

h8-h9-h10-h11 |

|

Cold Drawn and Ground |

10.00 - 75.00 |

5/6 - 2.50 |

h8-h9-h10-h11 |

|

Peeled and Polished |

40.00 - 150.00 |

1.50 - 6.00 |

h11, h11-DIN 1013 |

|

Peeled and Ground |

20.00 - 50.00 |

3/4 - 2.00 |

h9-h10-h11 |

2.4602 Hastelloy Round Bars Equivalent Grades

|

STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

EN |

|

Hastelloy C22 |

2.4602 |

N06022 |

NW 6022 |

NiCr21Mo14W |

ASTM B574 N06022 Rod and Bars Chemical Composition

|

Grade |

Ni |

C |

Cr |

Co |

Fe |

Mn |

Mo |

P |

Si |

S |

W |

V |

|

Hastelloy C22 |

Bal |

0.010 max |

20 – 22.5 |

2.5 max |

2 – 6 |

0.50 max |

12.5 – 14.5 |

0.02 max |

0.08 max |

0.02 max |

2.5 – 3.5 |

0.35 max |

Hastelloy Alloy C22 Rods Mechanical & Physical Properties

|

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

|

8.69 g/cm3 |

1399 °C (2550 °F) |

Psi – 1,00,000 , MPa – 690 |

Psi – 45000 , MPa – 310 |

45 % |

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China