|

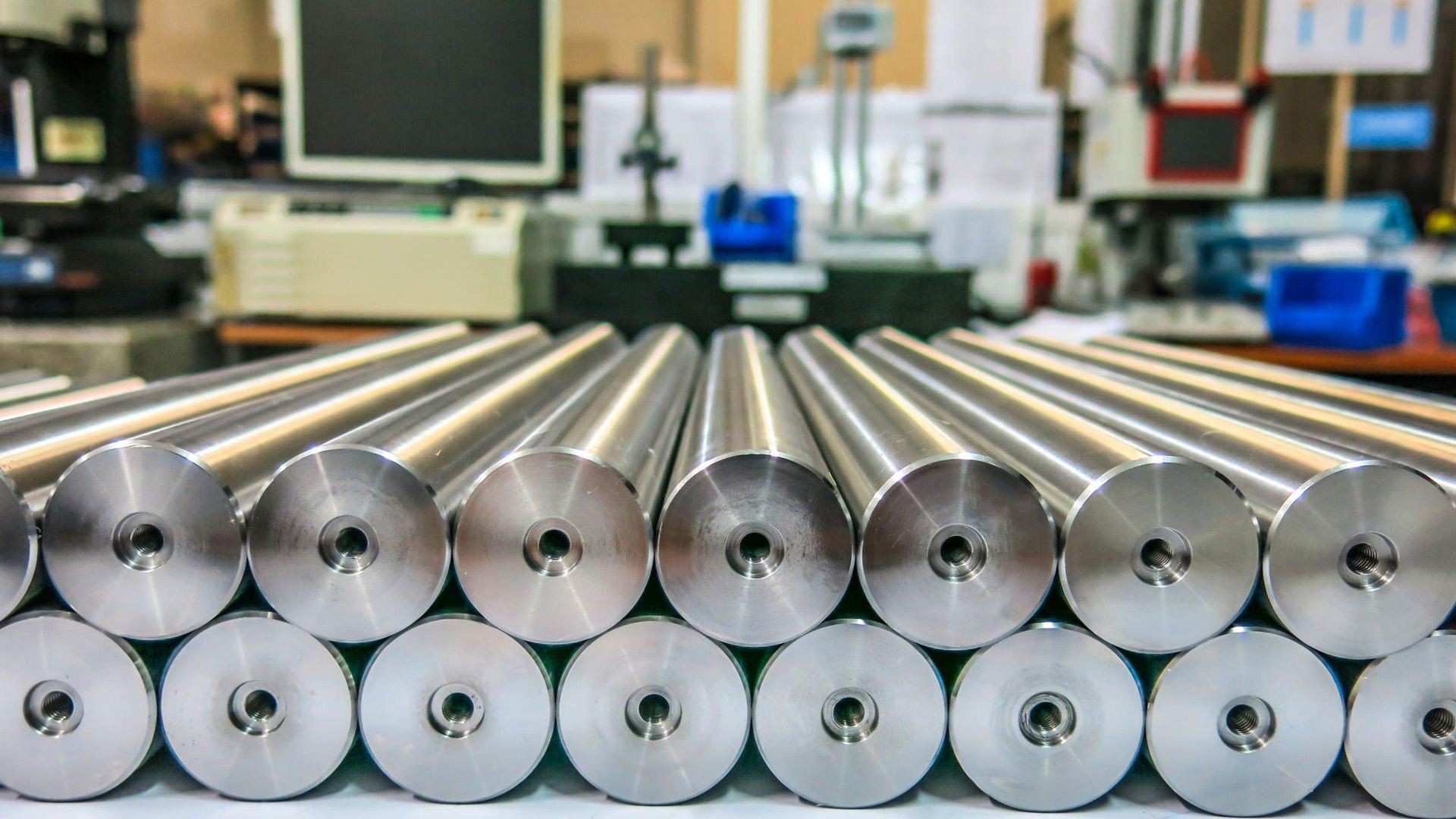

Round Bar DIA: 3 ~ 600 mm L: 0.5 ~ 6 m |

Hollow Bar DIA: 32 ~ 375 mm L: 0.5 ~ 6 m |

|

Hex Bar DIA: 3 ~ 180 mm L: 0.5 ~ 6 m |

Square Bar Side Width: 2 ~ 200 mm L: 0.5 ~ 6 m |

Chemical Composition

|

Grade |

C |

Si |

Mn |

P |

Cr |

Mo |

Ni |

N |

|

Alloy 28 |

0.02 max |

0.70 max |

2.00 max |

0.03 max |

26.00 – 28.00 |

30.00 – 32.00 |

19.00 – 21.00 |

0.11 max |

Mechanical Properties

|

Element |

Hardness |

Yield Strength (0.2%Offset) |

Tensile Strength |

Elongation |

|

Alloy 28 |

230 |

220 |

500 – 750 |

30 % |

Corrosion Resistance

Alloy 28 has excellent resistance to strong acids, including phosphoric, hydrochloric, nitric, formic, and sulfuric acids. Its resistance to pitting and corrosion resistance makes it suitable for seawater piping and heat exchangers.

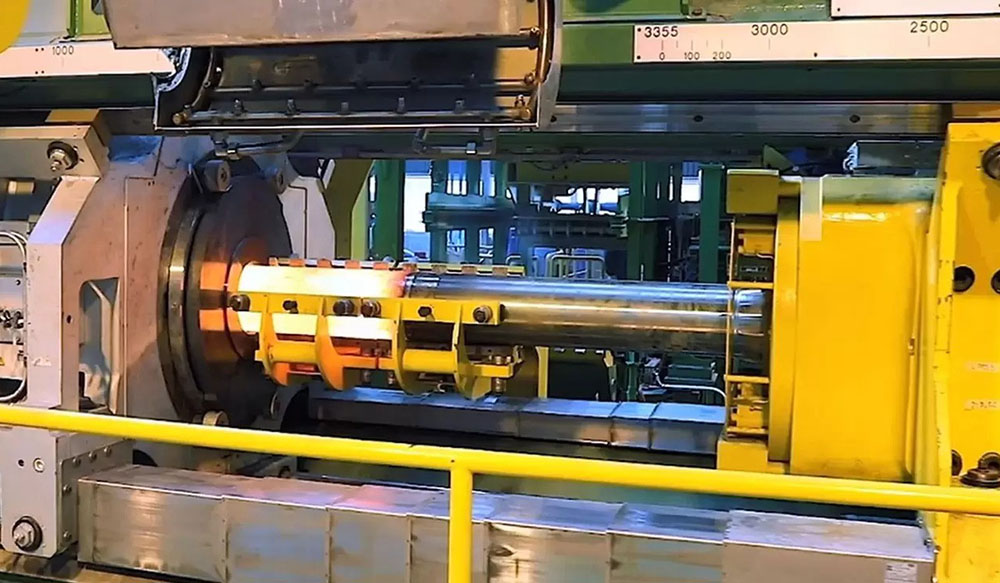

Heat treatment and working

Recommended working and heat treatment parameters for alloy 28:

Forging: 1150-850 ℃

Rolling: 1150-850 ℃

Solutioning: 1050-1150 ℃

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China