In metallurgy, particularly in the context of stainless steel, the terms 800, 800H, and 800HT refer to different variations of an alloy known as Incoloy 800. Here's a breakdown of the differences between these variants:

Incoloy 800:

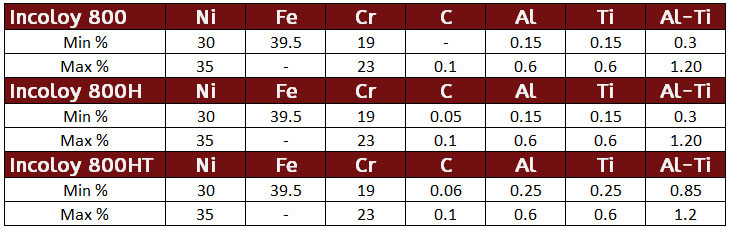

Composition: Incoloy 800 is a nickel-iron-chromium alloy with good strength and excellent resistance to oxidation and carburization at high temperatures.

Use: It is used in various applications such as furnace components, petrochemical processing, heat-treating equipment, and power generation.

Incoloy 800H:

Composition: Incoloy 800H has a higher carbon content compared to Incoloy 800, which improves its high-temperature characteristics.

Use: It is specifically designed for high-temperature applications such as nitric acid and ammonia atmospheres.

Incoloy 800HT:

Composition: Incoloy 800HT has even higher carbon content than Incoloy 800H, further enhancing its high-temperature properties.

Use: It is used in applications where exposure to high temperatures for prolonged periods is required, such as in industrial furnaces and heat-treating equipment.

Incoloy 800: Standard version with good strength and oxidation resistance.

Incoloy 800H: Higher carbon content for improved high-temperature characteristics.

Incoloy 800HT: Even higher carbon content for extended high-temperature applications.

These various grades allow for selection based on specific application requirements, especially when it comes to operating temperatures and environmental conditions.

2025-12-11 16:42:29

2025-11-19 14:09:22

2025-11-07 17:27:49

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China