Solid solution on mechanical properties

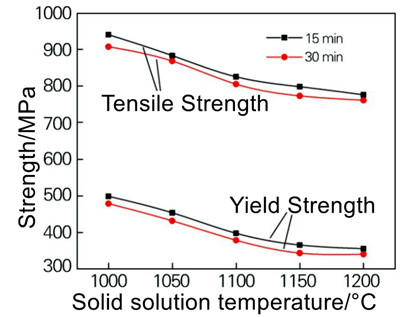

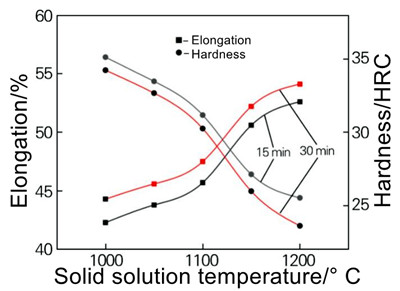

As the solid solution temperature increases, the hardness of the material shows a slow and then fast decreasing trend, and the elongation shows a slow and then fast increasing trend, as shown in Figure 10. The effect of solid solution temperature on hardness and elongation is also mainly from the precipitation phase and grain size in the material. As can be seen from Figure, at 1000 ℃ solid solution, the hardness of the material is high, the corresponding elongation is low, the precipitated phases in the matrix are many, and the grain size is small; the solid solution temperature is 1150 ℃, the hardness of the material is low, the elongation is high, and most of the precipitated phases in the matrix have been back to dissolve, and the grain size is large. In the holding time of 15 min, the intersection of the two curves appeared in the solid solution temperature of 1150 ℃; with the extension of the holding time, the intersection of the two lines shifted to 1130 ℃ near the intersection of the two lines, as shown in Figure. When the solid solution temperature exceeds the dissolution temperature of the precipitated phase, with the extension of the holding time, the precipitated phase is dissolved back in large quantities, and the grain growth is advanced, so the intersection of the two lines appears to be shifted forward.

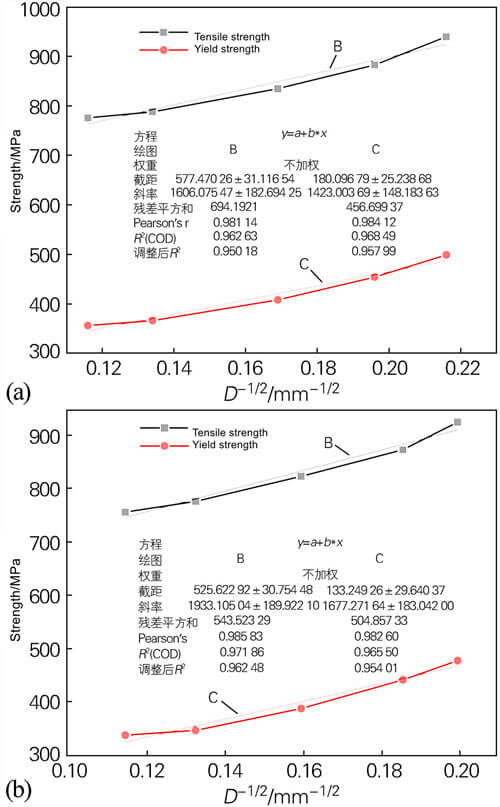

The microstructure greatly influences the strength of metallic materials. The grain size and strength of N06022 alloy under different solid solution temperatures are linearly fitted, as shown in Fig. 11. The relationship basically satisfies the Hall-Petch equation. The linear correlation coefficients of strength and grain size are 0.95, 0.96, 0.96, 0.95, respectively, which are close to 1, indicating that the credibility of the regression curve is high.

As the solid solution temperature increases, the strength and hardness of the material decrease, and the grain size and elongation increase. Combined with the results of this test, it can be seen that when the solid solution temperature is 1150 ℃, the tensile strength, yield strength, and hardness of N06022 alloy are lower, the elongation is higher, the precipitation phase in the matrix is basically back to dissolve, and the grain size is also larger. Solid solution 15 min, solid solution temperature of about 1150 ℃, hardness and elongation curves appeared intersection, indicating that the comprehensive mechanical properties at this time are better.

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China